NANOXD

SUPERIOR pERFORMANCEThe Engine Treatment with NanoPolisher

Ground-breaking Technology for Motor Oil

NanoXD Diamond-Like Carbon Coating

Backed by years of research on the power of graphene for anti-wear. Watch an introduction from Argonne Labs (US Department of Energy) on the research and possibilities of the new super-lubricity technology, which is now possible with

NanoXD

Take YOUR Engine to new Extremes.

NanoXD NanoPolishing Treatment will boost your engine torque and reduce fuel consumption. Operate at high RPM with minimal stress, minimizing damage and extending engine life. Experience the ultimate in performance and efficiency with NanoXD.

Testimonial

“I’m saving more than $1,200.00 on my long trips between Florida and California with my 2017 Volvo. This product is giving me more than 30% savings on Fuel. I’m recommending it to everyone now.”

Intro

Revolutionize Your Engine Performance with NanoXD

-

NanoXD is a groundbreaking nanocarbon technology that polishes metals at the molecular level.

-

The NanoPolisher forms a protective graphene coating, reducing engine roughness and friction during operation.

-

Recommended for all sealed mechanical gear systems, engines, turbines, and bearings, making current lubricant additives obsolete.

-

This advanced technology PERMANENTLY REMOVES friction sources in engines by eliminating surface asperities on machined metal parts.

-

Experience significant increases in fuel economy and power/torque, along with over 90% reductions in harmful carbon emissions. With NanoXD, enjoy increased reliability and longevity of your equipment. Keeping engines running perfectly clean for hundreds of thousands of miles.

Benefits & advantages:

Fuel Economy

-

Fuel Savings is the main benefit for treating your engine with NanoXD.

-

The treatment will pay by itself quickly due to the immediate improvement in the engine performance and fuel savings, especially for those running long trips.

Performance

- Improve torque

- Enhance true HP capacity at lower RPM

-

Boost overall engine efficiency with fewer breakdown

Longevity

-

Extend engine life

-

Reduce heat build-up from friction

Environmental Impact

-

Lower emissions and eliminate the need for high-efficiency catalyzers

Operational Improvements

-

Quickly reduce engine noises from un-tuned engines

-

Decrease engine vibrations, especially noticeable in medium and large engines.

Savings and Return on Investment

-

Most customer are experiencing a better engine running smoother with lower fuel consumption

-

Reduce emission control expenses

-

Minimize engine breakdown maintenance costs

-

Decrease the need to manage driver’s idle engine or high RPM habits

-

Increase vehicle availability, reducing downtime

-

Boost overall net profit when calculated on cost-per-mile basis

-

Enhance your vehicle’s resale value

HOW IT WORKS

-

Nanopolisher works by forming a protective layer of graphene, the 21st-century wonder material, while the engine is running. The heat generated by friction in the engine creates graphene spheres that bind to the surface of metal parts.

-

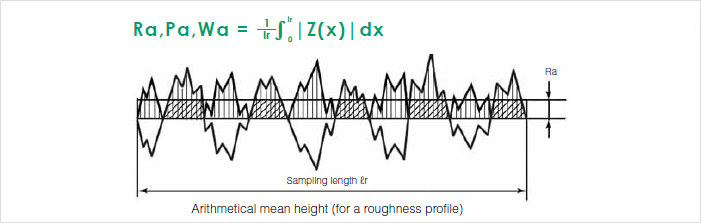

These graphene spheres smooth out the rough surface imperfections of metal parts, polishing them to near atomic-level perfection. This process eliminates 99% of surface roughness (Ra = <4 nm, RMS = <5 nm). Additionally, the spheres trap metal wear particles, preventing further abrasion.

-

The result is a more efficient, longer-lasting engine with reduced friction and wear.

Graph of Metal Surface Rugosity (Ra) Picture of graphene sphere over metal surface:

Testimonial

“In my 34-year career with Exxon International, I never saw anything even close“

W. DAVID MCCOY. Former Exxon Lubricant Specialist.

As the Nanopolisher cuts through the rough surface, the roughness level (Ra) is reduced, see the test below where initial Ra = 221.6 nm and has been polished to Ra = 3.4

The formed Nanocarbon spheres then remain permanently coating the surfaces of the parts, preventing future metal-to-metal contact. These NanoCarbon sphere are made of the hardest substance known to mankind (Graphene Oxide) and are harder than diamond.

NanoXD technology is a revolution in super lubricity for motor oil that permanently removes the source of all friction in engines – the asperities on the surfaces of machined metal parts. As asperities are removed from the surface of the metal parts, increasing fuel economy due to reduction in power and torque losses, along with drastic reductions (>90% max.) in harmful carbon emissions and increased reliability and longevity of equipment. With atomic-level perfection of engine parts, no harmful excessive hots spots are created, meaning engines stay perfectly clean (without engine sludge) for hundreds of thousands of miles!

Recent real-world testing of Freightliner Class 8 (OTR) semi truck showed between 21.5% and 22.9% gains in fuel economy. These tests were done over 1,200 mile and 3,700 mile evaluation legs through 14 U.S. states.

The below pictured engine and oil was inspected after 220,000 miles

Image of Oil Pan treated with NanoCarbon:

Other motor oil’s EP/AW additives that attempt to coat surfaces cannot eliminate friction, only providing limited improvements.

NanoXD is fully compatible with all motor oils and current additives (except those containing Molybdenum Disulfide) and its use will not void any manufacturer’s warranty.

For instructions on how to apply, check here

AUTOMOBILE ENGINES

- NanoXD technology has been tested in controlled environment, On-The-Road tested and also it’s already in use in real-world environment, running on engines on different types of vehicles:

- Automobile running for more the 200,000 miles

- Stock Car Racing – Used on several vehicles on regulated Stock Car Racing competition.

- Long-Haul Trucks – Used by trucks such as Volvo, Freightliner Class 8 (OTR) with interstate routes

As stated by formed Exxon Lubricant Specialist and Car Enthusiast:

“Incredible results “even” if I hadn’t experienced over 10% improvement on my first tank of gas after one treatment in my Acura NSX. This product will revolutionize lube technology. In my 34-year career with Exxon International, I never saw anything even close, and one of my assignments was International Lubricants and Specialties Manager.” By W. DAVID MCCOY – former Exxon Lubricant Specialist June 16, 2016

Looking for Right Oil for your vehicle? Check here your product:

MARINE ENGINES

- NanoXD technology has been tested on high speed racing boats with great results on:

- Increase on Torque

- Fuel Economy

- Engine Reliability

All sealed engines benefit from metal improvements, such as NanoPolishing at molecular level.

AIRCRAFT ENGINES

- NanoXD technology has been tested on single engine and multi engine aircraft. Results have shown an a promising improvement on aircraft engine reliability:

- Reduction on Engine Noise, due to decrease on engine friction

- Fuel Economy

- Engine Reliability

All sealed engines benefit from metal improvements, such as NanoPolishing at molecular level.

OUR COMPANY

Our Leadership Team

Luiz Januario

President and Co-Founder

Luiz has more than 30 years of experience with advanced technologies, from Banking to Financial Investment systems to Ethanol processing, Auto-Parts and most recently as Senior Solution Architect in the Transportation, Logistics and Supply Chain industry.

You can reach Luiz Januario at [email protected]

Phone: 954-328-2893 / 1-877-727-6468

Alexandre Chalela

Business Director for Development and Sustainability - Co-founder

Alex Chalela joined NanoXD after more than 25 years in the restaurant industry.

Our Locations

USA

Suite 204, Lakeside Corporate

Weston, FL USA

Brazil

Galeria Ribeiro

Várzea Paulista / Jundiaí, SP – Brasil